Molding replacement collision repair involves skilled technicians using advanced tech and knowledge to precisely remove and replicate plastic exterior components for both aesthetics and functionality. Comprehensive documentation ensures accurate, transparent work restoring vehicles to pre-accident conditions. Efficient workflows and standardized processes, guided by detailed documentation, enhance productivity, communication, and training, setting industry benchmarks in molding replacement collision repairs.

In the realm of automotive repairs, documentation plays a vital role in ensuring quality and safety, especially for intricate tasks like molding replacement collision jobs. Understanding the intricacies of this process is essential for professionals aiming to deliver top-tier services. This article delves into the significance of detailed documentation, highlighting its critical function in streamlining workflows, maintaining industry standards, and ultimately, fostering customer satisfaction during molding replacement collision repairs.

- Understanding Molding Replacement: A Collision Job Essential

- Documentation Role: Ensuring Quality and Safety in Repairs

- Efficient Workflow: Streamlining Molding Replacement Processes

Understanding Molding Replacement: A Collision Job Essential

In the realm of automotive collision repair, molding replacement is an intricate yet vital process that forms a significant aspect of restoring vehicles to their pre-accident condition. This procedure involves the precise replication and installation of plastic components, commonly known as moldings, which adorn a car’s exterior. These moldings not only contribute to the aesthetic appeal but also serve crucial functional roles, such as sealing gaps and protecting underlying structures from elements like water and debris.

Effective molding replacement collision jobs demand meticulous attention to detail and a deep understanding of both automotive design and material properties. Skilled technicians utilize specialized tools and techniques to remove damaged or deteriorated moldings, ensuring minimal disruption to the overall vehicle structure. Subsequently, they carefully replicate these components, often with the aid of advanced manufacturing technologies, matching them precisely to the car’s make and model. This level of precision is essential for achieving seamless integration, enhancing the vehicle’s overall appearance and performance, and providing customers with top-tier car paint services and fender repair solutions.

Documentation Role: Ensuring Quality and Safety in Repairs

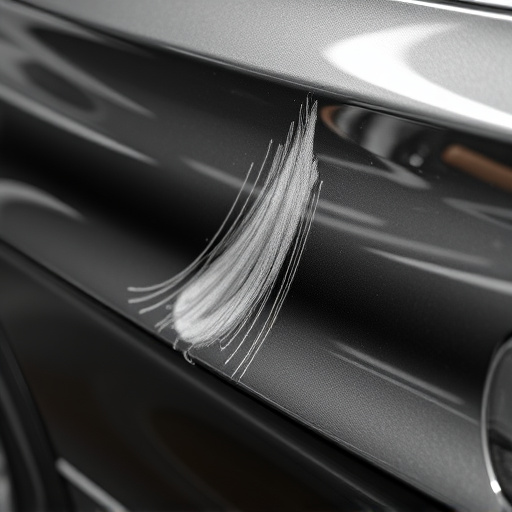

Documentation plays a pivotal role in ensuring the quality and safety of molding replacement collision jobs. In the intricate process of repairing vehicles, every detail matters, and comprehensive records serve as a guardrail against errors and subpar workmanship. A well-documented procedure includes meticulous notes on the extent of damage, parts required, and the sequence of repairs, allowing for consistent, accurate replication across different projects.

This practice is especially vital in collision repair services where precision is key to restoring vehicles to their pre-accident condition. Body shop services that prioritize documentation create a transparent trail, enabling clients to understand the work done and fostering trust. Moreover, detailed records facilitate effective communication among team members, ensuring everyone involved in the car repair shop’s operations is aligned and working towards the same goal— delivering superior molding replacement collision repairs.

Efficient Workflow: Streamlining Molding Replacement Processes

Efficient Workflow: Streamlining Molding Replacement Processes

In the realm of collision repair services and vehicle body repair, efficient workflows are non-negotiable for achieving top-notch results. When it comes to car body repair, a well-documented process ensures that every step is executed with precision and consistency. This is particularly crucial in molding replacement collision jobs, where even minor inconsistencies can lead to structural weaknesses or cosmetic imperfections. By documenting each phase of the repair, from initial assessment to final inspection, technicians can maintain a standardized approach, minimizing errors and maximizing customer satisfaction.

Streamlined processes not only enhance productivity but also foster better communication among team members. Detailed records enable quick reference during complex repairs, ensuring that no detail is overlooked. This documentation becomes an invaluable resource for training new personnel, allowing them to grasp the intricacies of molding replacement collision jobs with ease. Ultimately, efficient workflows and comprehensive documentation contribute to delivering high-quality vehicle body repair services, setting a benchmark for excellence in the industry.

Proper documentation is an integral part of any successful molding replacement collision job, ensuring that repairs are not only efficient but also safe and of high quality. By meticulously recording each step of the process, from material specifications to installation techniques, professionals can maintain consistent standards and accommodate future reference or adjustments. This meticulous approach streamlines workflows, reduces errors, and ultimately enhances customer satisfaction in a competitive market where precise, documented work is highly valued.